Jack Daniel’s has been made the same way for over 150 years and while the basic process is the same the world over, Jack Daniel’s has its own distinct methods and practices which is what gives their whiskeys their unique character. I wanted to find out more about this and here’s what I learnt distilled (sorry for the pun) into 7 steps.

1. Getting the Ingredients – Grain, Water & Yeast

There may only be three ingredients in whiskey but there’s lots of room for variation which affects the final product.

The Jack Daniel’s mash bill (fancy word for grain recipe) is: 80% corn, 8% rye and 12% malted barley. The high corn content – which is far more than you’ll find in many other whiskeys, is part of the reason for the whiskey’s sweetness, while the rye gives it some pepper and spice flavors.

Only high-quality grains with a high starch content (it’s the starches that will be converted into sugars and then alcohol) is used. The grains are uncracked, clean and sorted which means no foreign materials can get inside and contaminate them, and negatively affect the taste the whiskey.

In 2017 Jack Daniel’s started producing a rye whiskey with a mash bill of 70% rye, 18% corn and 12% malted barley.

The natural spring water used to make Jack Daniel’s whiskeys comes from a two-mile deep limestone cave on the distillery’s site. The water is crisp, cool, clean and pure and because it has passed through many layers of limestone has had any iron removed. This is good because iron reacts with alcohol turning it black and bitter – the very opposite of the smooth that Jack Daniel’s whiskeys are known for.

It’s not just a happy coincidence that the distillery has the perfect water source for making whiskey so close to hand. Jack Daniel’s bought the land containing the cave for a small fortune because he knew what its water would do for his whiskey.

Like many distilleries Jack Daniel’s uses their own strain of yeast to maintain consistency.

2. Mashing – Converting Starches into Sugars

All the grains are ground down into a coarse flour and the corn and rye are cooked with the spring water from the cave in a mash cooker to break down the cellulose walls that contain the starch granules.

The malted barley (barley that has been soaked in warm water, partially germinated, and then dried to access its starches) is added because when the barley grain opened the starch secreted the enzyme amylase which is excellent for converting starch into sugar.

That means other chemical enzymes are not needed for that, which is good because it would add undesirable elements to the final product. Using only the natural enzyme of the malted barley keeps the mash pure and free from unwanted tastes.

Several hours of stirring later and the starches from the grain will have been converted into sugars. The result is a thick, porridge-like liquid called mash which is then sent to the fermenter.

3. Fermentation – Converting Sugars into Alcohol

The yeast is now added so the fermentation process can begin.

Some of the spent grains from previous batches are used to start fermentation on this new batch. This helps control the growth of bacteria – which could negatively impact the whiskey’s taste, and improve the consistency and quality of the whiskey.

It’s called the sour mash process (which is why Jack Daniel’s is a sour mash whiskey) not because the mash is sour but because the technique is the same as the one used to make sourdough bread, where leftovers from the previous batch are reused in the process of fermenting the new one.

The yeast and the mash will sit in the fermenting tanks for 4 – 6 days after which you will have a liquid (called distiller’s beer) of about 12%ABV.

4. Distillation – Converting 12% ABV Into 70% ABV

Distillation is the process of separating different parts of a liquid by heating it until it becomes a vapor and condensing it back into liquid, taking advantage of the fact that different substances have different boiling points. In making whiskey, distillation takes advantage of the fact that alcohol boils at a lower temperature than water so it can be separated from the rest of the liquid, concentrated, condensed and collected.

The distiller’s beer is pumped into column stills (as opposed to pot stills that are used for making malt whiskeys). Like many other distilleries, Jack Daniel’s stills are made from copper which helps strip spirits of certain unwanted flavor and aroma compounds that would make it unpleasant to drink.

The liquid is poured in from the top while hot steam rises from the bottom. The liquid flows downwards through layers of trays and when it meets the steam the alcohol part vaporizes and collects at the stop of the still while the rest of it falls to the bottom.

The alcohol vapor then passes through a series of coils which cools it and condenses it back into liquid. Unlike other whiskeys that are distilled two or even three times, Jack Daniel’s is distilled just once. That’s because the more you distill the liquid the more the flavors from the grain are removed. And since Jack Daniel selected his mash bill because of its flavors, he wanted to retain as much of them as he could as it went through the distillation process.

Jack Daniel’s distills their whiskeys to 70%ABV / 140 proof.

5. Filtering the Distillate through Charcoal

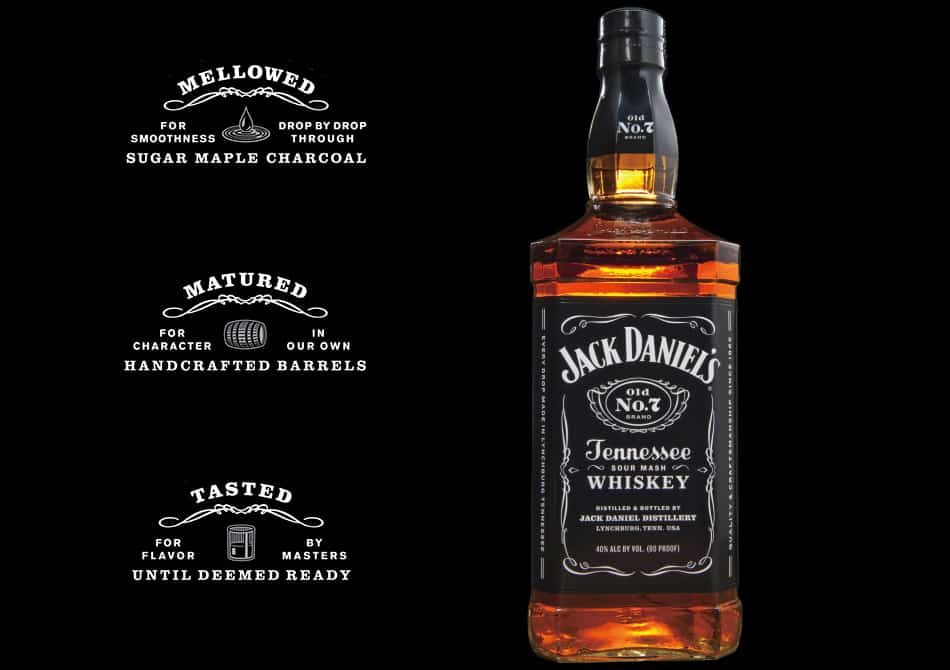

Called the Lincoln County Process or charcoal mellowing all Tennessee whiskeys are filtered through charcoal after distillation to eliminate impurities, mellow the flavor and jump start the aging process.

Jack Daniels’ make their own charcoal. They do this by dousing pallets of hard sugar maple with raw unaged Jack Daniel’s whiskey and setting it on fire. They use Jack Daniel’s distillate as fuel so that no petroleum taste will be added to the whiskey during the filtration process.

They also grind the charcoal down into smaller pieces to increase the surface area for the off-flavor molecules that are being filtered out, to stick to.

10-foot-deep tanks / vats are filled with this charcoal. The distillate is poured in and works its way to the bottom over three to five days.

It’s this step that gives Jack Daniel’s its distinctive smoothness and with the bitterness from the grain and yeast filtered out, the distillate is already soft and mellow even before its placed into barrels for aging.

Jack Daniels produces a whiskey that is charcoal filtered twice. Gentleman Jack is filtered both before going into the barrels as normal and for the second time after being matured before it’s bottled. The purpose of this is to remove any remaining impurities and further mellow the whiskey so that it’s even smoother than the smooth Jack Daniel’s is known for.

The second filtering is only through three feet of charcoal because if it was through the full ten feet, too much of the whiskey’s flavor would be filtered out too.

6. Aging / Maturing the Whiskey in Barrels

The distillate is place into new, charred, American oak barrels so that it can pick up flavors from the wood. This happens because during the time the whiskey is stored, changes in temperature causes the barrels to expand and contract and the liquid to seep in and out of the wood, where it picks up its characteristic color and flavors in the process.

Jack Daniel’s estimate that their whiskeys get 60% – 70% of their flavor during the aging process, which is why Jack Daniel’s make their own barrels.

One of their whiskeys is aged in barrels made in a unique way. The Sinatra Select (a whiskey Jack Daniel’s created to pay tribute to Frank Sinatra who had a lifelong friendship with the brand), is aged in barrels that have deep grooves carved into their staves. This gives the whiskey more exposure to the oak, so it will acquire more flavor than the standard Jack Daniel’s expressions.

The whiskey is stored in warehouses, but the exact position inside will affect the maturation process because the environment will be different. The Jack Daniel’s single barrel expressions come from barrels stored in the uppermost part of the warehouse, where increased changes in temperature cause they whiskey’s color to deepen and its flavors to become more intense.

On the other hand, Gentleman Jack comes from barrels stored in the mid-level of the warehouse and below, which is why it’s a softer and more subtle whiskey.

Unlike many other distilleries that age their whiskeys for a specific amount of time beyond the legal minimum, Jack Daniel’s uses taste as well to determine when a whiskey has matured. Once a barrel has been aged for four years, it will be sampled every few months by one of their tasters, who will determine based on its flavor if the whiskey is ready.

This means that all Jack Daniel’s whiskeys are at least four years old, but some (depending on the product) can be closer to seven years old.

7. Bottling the Different Expressions

Once ready, the whiskey is diluted (it went into the barrel at 70%ABV) with water and bottled.

Old No. 7, which is the Jack Daniel’s standard expression is diluted to 40%ABV, but the single barrel expressions are diluted to 45% or 47%ABV because a higher alcohol content level means you retain the nuances from the different barrels, which is the whole point of single barrel expressions.

Cask-strength whiskeys are bottled straight from the barrel at its full proof and not diluted and Jack Daniel’s cask-strength expressions are anywhere between 62.5% – 70%ABV.

Jack Daniel’s also produces whiskey drinks that are not technically whiskeys (because they’re diluted to 35%ABV), but a blend of Old No. 7 and one of their own liqueurs – honey, cinnamon or apple. These drinks combine whiskey with sweet, spicy or apple flavors.

And that’s how Jack Daniel’s whiskeys are made.

The truth is that there’s one more step in making Jack Daniel’s whiskeys and that’s drinking them. This sounds counter intuitive as consuming is the opposite of producing, but let’s face it, if we didn’t drink it, they wouldn’t make it.

You can buy Jack Daniel’s whiskeys at drizly.com here .

.