Whiskey is a popular drink, which probably has a lot to do with its high alcohol content level. That’s why I wanted to know exactly how whiskey gets its alcohol. I looked into it and here’s what I found.

Whiskey gets its alcohol from the grain ingredients with which it’s made. The starches in the grain are converted into sugars and the sugars are converted into alcohol, which is then distilled and after maturation diluted to at least 40%ABV.

If that’s too vague, don’t worry. The rest of this article will look at how whiskey gets its alcohol and alcohol content level in more detail.

How Whiskey Gets Its Alcohol

As mentioned, whiskey gets its alcohol from the grain ingredients with which it’s made. In fact, the first half of the whiskey making process is all about turning grain into alcohol. Here’s how that happens.

First, starch containing grains such as barley, corn, wheat, oats or rye are specially treated to break down their cellulose walls and make its starches accessible. Barley grain is malted – meaning it’s soaked in warm water, left to partially sprout or germinate and then dried in a kiln, whereas other grains are ground in a gristmill and cooked with water.

The malted barley or cooked grain is then put into a large vessel called a mash tun or tub and mixed with warm water to convert the starches into sugars. It’s stirred for several hours after which the mixture becomes a thick porridge-like sugar-rich liquid known as mash.

The mash is cooled and pumped into large tanks called washbacks. Yeast is added so the mixture, now known as wort, can ferment. It takes 48-96 hours for the yeast to turn the sugars into alcohol and some distilleries let it go on for longer.

Although the future whiskey already has its alcohol, the process is not quite over. The alcohol content of the liquid (now called distiller’s beer) is only about 5%-10%. Distillation will make it anywhere between 65%-95%, by turning the alcohol part into vapors (alcohol has a lower boiling point than water), separating them from the rest of the distiller’s beer, and condensing them back into liquid.

Distilleries can decide how much to distill their whiskeys, as long as it’s not more than the legal maximum, which varies from country to country. The following table shows the most common examples:

| Country | ABV |

|---|---|

| Scotch whisky | 94.8% |

| Irish whiskey | 94.8% |

| Bourbon | 80% |

The reason why whiskey isn’t distilled to 100%ABV is because that would remove all the flavor from the grain. Distilleries therefore distill whiskey to a higher or lower ABV (between 65%-95%) depending on how much flavor from the grain they want to keep.

However high the alcohol content of whiskey after distillation, it’s diluted with water before being placed into barrels for maturing. Again, distilleries can decide how much the dilution will be, although Scotch whiskies are usually placed in barrels at 60%-70%ABV, and American whiskeys must be placed in barrels at no more than 62.5%ABV.

| Country | ABV |

|---|---|

| Scotch whisky | Usually 60% -70% |

| American whiskey | Can’t be more than 62.5% |

The whiskey will now spend at least three years maturing – and often it’s far longer, during which time it picks up about 70% of its flavor. Nonetheless, after maturation most whiskeys are diluted once again to its final alcohol content level (no less than 40%ABV), before being bottled.

How Whiskey Gets Its Alcohol Content Level

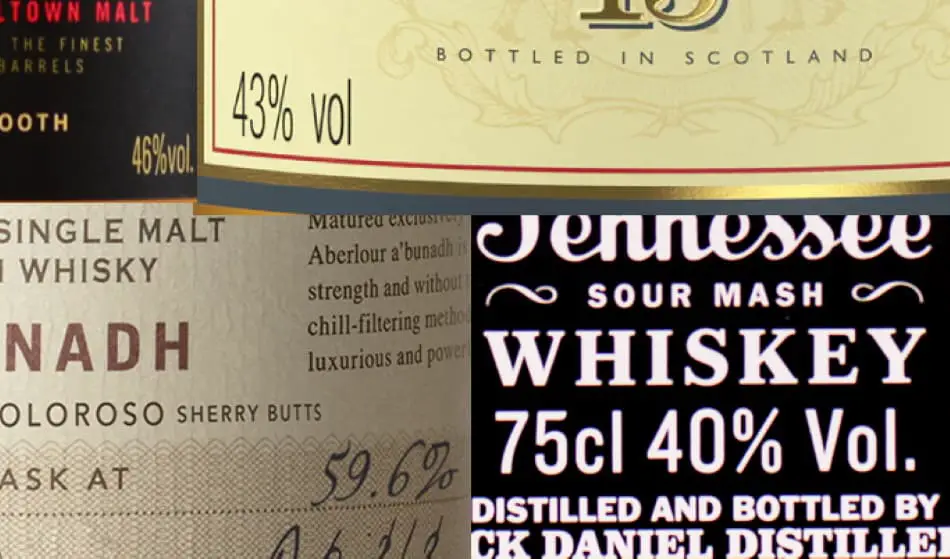

As we’ve seen, whiskey gets its alcohol from the way it’s made. It also gets its alcohol content level the same way – through a combination of distillation and dilution, with many whiskeys ending up being 40%, 43% or 46%ABV. Here’s why.

Why Many Whiskeys Are 40%ABV

The reason why many whiskeys have an alcohol content of 40% is because, in most countries, that’s the legal minimum bottling ABV for whiskey. This is not because there’s an intrinsic need for whiskey to have at least this amount of alcohol, but purely because of historical factors.

During the First World War, the UK passed legislation to curb liquor consumption. By 1917 the alcohol level of Scotch whisky could be no less than 28.6% and no more than 40%. While this restriction was lifted after the war, in 1920 the duty on whisky was raised and the distillers were banned from adding this tax to the whisky’s price. This meant that making whisky above 40%ABV became cost prohibitive for many years.

With everyone accustomed to 40%ABV whisky, that became its minimum alcohol level in the 1988 Scotch Whisky Act.

In the United States during the era of prohibition, bootleggers added more water to whiskey to stretch their supplies and after prohibition stronger whiskeys were still in short supply. In the 1960s vodka and light rum became very popular and major whiskey brands wanted to take advantage of this low-alcohol-content trend. They started making whiskeys at 40% and 43%ABV which also became popular, so they became a staple of the industry.

Why Many Whiskeys Are 43%ABV

The reason a lot of whiskeys have an alcohol content of 43% is to do with the balance between flavor and cost.

The amount of alcohol in whiskey has a huge impact on its flavors because alcohol carries flavor compounds. This is why whiskeys with a higher alcohol content have more intense and concentrated flavors. The downside is that whiskeys with a higher alcohol content also have a higher alcohol tax and therefore, a higher price.

A 43%ABV whiskey is probably the highest you can go for more intense flavors before the increase in price due to alcohol tax becomes too much for many people.

Why Many Whiskeys Are 46%ABV

The reason why many whiskeys have an alcohol content of 46% is because it removes the need for whiskey to go through a process called chill filtration.

Whiskey contains fatty acids, esters and proteins that dissolve in alcohol but not in water. When the alcohol concentration becomes too low or the whiskey too cold (lower than room temperature) these molecules un-dissolve, clump together and make your whiskey cloudy.

This is a problem for distilleries because many people add water to their whiskey to dilute it or ice to cool it, so there’s a good chance consumers will end up with a cloudy whiskey and think that there was something wrong with it.

To prevent this, distilleries put many of their whiskeys through a process called chill filtration. The whiskey is chilled so that the fatty acids, esters and proteins un-dissolve, and it’s then passed through a series of filters to remove them. Now the whiskey can no longer become cloudy.

The only problem is that these fatty acids, esters and proteins contain a lot of flavors, which are therefore removed too.

So, distillers started to make whiskey at 46%ABV because at that level of alcohol the fatty acids, esters and proteins will remain dissolved even if cooled. The whiskey won’t go cloudy so there’s no need to chill filter it and it will therefore keep all its flavorful compounds.